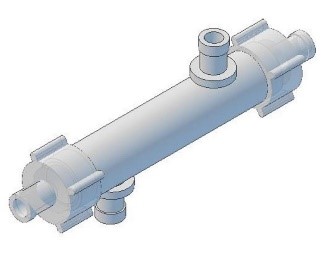

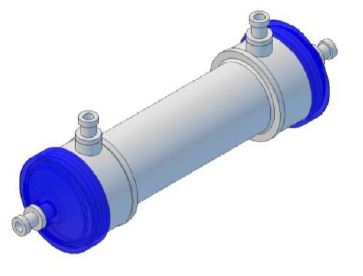

Hollow Fiber Oxygenators

Flowing liquid media can be safely and efficiently oxygenated by a hollow fiber gas transfer cartridge which offers a convenient way to achieve high mass transfer of gases: oxygen, carbon dioxide etc. These compact hollow fiber oxygenator cartridges incorporate very hydrophobic polymethylpentene hollow fibres. Used in organ perfusion and in-vitro modelling projects, for example, and for bubble-free oxygenation in bioreactors and fermenters. Produced in an ISO 13485 accredited facility. See specifications table below.

A hollow fiber oxygenator uses an extremely hydrophobic fiber that excludes liquid but allows gas transfer. Whereas older style hollow fiber oxygenators used a symmetrical fiber that was prone to “weeping” of medium or blood through the fiber during extended use the asymmetric structure of Polymethylpentene (PMP) fibers prevents this from happening.

The dense outer dense skin not only prevents entry of liquids through the pores during prolonged use but also maintains excellent gas diffusion performance because of its extremely small thickness.

The high porosity and uniform pore distribution in the capillary wall ensures outstanding permeability of oxygen and carbon dioxide, while the thin outer skin avoids the direct contact of liquids and gas.

| KDBIO Cat.# | KDA0045-S | KDA0046-S | KDA0047-S |

| Inner fibre surface area | 160 cm2 | 1900 cm2 | 2900 cm2 |

| Max. operating pressure | 1.5 bar | ||

| Hollow fibre membrane | PMP-2, Polymethylpentene | ||

| Hollow fibre geometry (ID/OD) | 200 µm/ 380 µm | ||

| Housing | Polycarbonate | ||

| ICS connectors | Female Luer | ||

| ECS connectors | Female Luer | ||

Advantages of PMP fibers

- High gas permeability: PMP fibers have excellent gas permeability properties, particularly for oxygen and carbon dioxide. This means that oxygen and carbon dioxide can efficiently diffuse through the fiber walls, enabling effective gas exchange between the blood or perfusion solution and the oxygen stream. High gas permeability enhances the oxygenator’s efficiency and ensures optimal oxygenation of the blood or perfusion solution.

- Low surface tension: PMP fibers have a low surface tension compared to other materials commonly used in oxygenators, such as polypropylene. This property helps prevent the formation of surface clots or bubbles, reducing the risk of clotting and ensuring uninterrupted gas exchange. It allows for smooth blood or perfusion solution flow across the fibers’ surface, minimizing the potential for clotting and enhancing the device’s biocompatibility.

- Biocompatibility: PMP fibers are generally considered to be biocompatible. They have a low tendency to trigger adverse reactions or inflammation when they come into contact with blood or other biological fluids. This biocompatibility is essential for maintaining the integrity of the blood or perfusion solution during oxygenation and minimizing the risk of complications or immune responses in patients.

- Mechanical strength and durability: PMP fibers exhibit good mechanical strength and durability, making them suitable for long-term use in medical devices like oxygenators. They can withstand the mechanical stresses and pressures associated with blood or perfusion solution flow without compromising their structural integrity. The durability of PMP fibers ensures that the oxygenator can perform reliably over an extended period, making them a favorable choice for clinical applications.

- Chemical resistance: PMP fibers have excellent chemical resistance, which is advantageous for withstanding exposure to various substances used in medical procedures. They are resistant to degradation by many chemicals, including sterilization agents and cleaning solutions. This resistance allows for effective sterilization and cleaning of the oxygenator without compromising its structural or functional integrity.</li<Overall, the advantages of PMP fibers, such as high gas permeability, low surface tension, biocompatibility, mechanical strength, durability, and chemical resistance, make them a favorable material choice for constructing oxygenators. These properties contribute to efficient gas exchange, reduced clotting risk, enhanced biocompatibility, and long-term device performance, all of which are critical for successful oxygenation in medical applications.