Culturing hybridoma cell lines for monoclonal antibody production in EZ-Flask saves user time, incubator space and provides easy and economical protein expression.

Below you will find detailed descriptions of the major features of this simple yet powerful bioreactor.

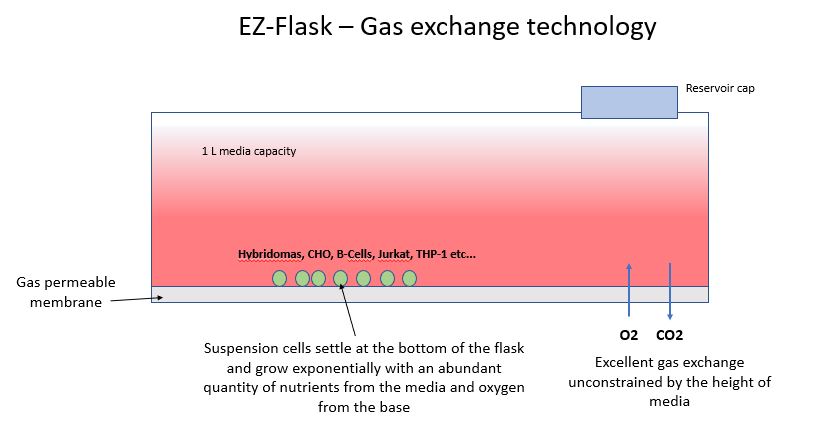

Gas exchange technology

The issue with traditional T-Flask cell culture is the limited amount of media, and thus nutrients, available to the cells. Adding too much media would result in very poor gas diffusion and cells would quickly suffer from oxygen deprivation. However, this issue is non-existent with EZ-Flask and up to 1 litre of media can be added in the flask. This is because the base of EZ-Flask is a silicone gas exchange membrane.

EZ-Flask is a compact bioreactor that works with Wilson Wolf’s gas exchange technology. It has a semi-permeable silicone gas exchange membrane at its base to permit efficient and continuous oxygenation over a long period of incubation without the need for cell passaging. The base membrane surface area is 200cm2. This allows excellent oxygenation for culturing hybridoma cell lines for monoclonal antibody production. The gas exchange interface at the base of the culture flask means that cells can grow exponentially for long periods of time without any other user intervention.

Typically, experiments in EZ-Flask will run anywhere from 15 to 30 days.

Moreover, as with any static flask device the EZ-Flask can be considered as a tool for cell culture experimentation, protocol development and for routine batch production. However, with EZ-Flask no cell passaging is required.

Media capacity

The EZ-Flask bioreactor has a 1L media capacity. Following inoculation, suspension cells can grow exponentially over a period of days limited only by the type and amount of media used. Thus, the EZ-Flask bioreactor provides a very convenient means to generate large numbers of cells and to produce, for example, a significant small batch quantity of high titer monoclonal antibody. With a good clone, the 1 Litre EZ-Flask bioreactor might produce around 150mg of monoclonal antibody from hybridomas. User interventions can be limited to filling, inoculation and the final harvest.

Gentle device – No shear stress and cell damage

Roller bottles, see-saw bioreactors, T-Flasks, and other cell culture devices necessarily require regular user intervention and some form of motion in order to oxygenate the culture, greatly impacting the cells through shear stress. EZ-Flask does not induce shear stress on the cells since no user intervention is required for culturing the hybridomas for monoclonal antibody production. EZ-Flask is a gentle static culture device.

Avoids weekend work

Thanks to its simple design, the EZ-Flask is very easy to use. Additionally, it leverages powerful gas exchange technology to easily produce significant amounts of protein. EZ-Flask saves incubator space and will replace from 20 to 100x T175 Flasks. No passaging work is needed and no weekend work should be required.